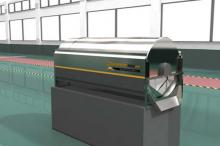

Cassava Sieving Machine - Starch Hydrocyclone

Processing Capacity: 25m3/hour

Application Scope: Starch milk concentrating and refining

Product Introduction: Starch hydrocyclone, cassava sieving machine, starch refining machine for cassava starch processing

Product Application of Starch Hydrocyclone

1. The automatic starch production line in washing, refining, clarifying procedure, separating partial protein, fine fiber, and soluble impurities from starch mash to improve fineness and whiteness of starch;

2. Replace the traditional starch processing with sedimentation tank, improve processing efficiency, ease the manual labor strength, and improve the starch quality;

3. Adopts liquid-liquid, solid-liquid separation technology, the different combination can independently complete the separating, washing, clarifying, concentrating and sifting of starch, modified starch, food, medicine, fermentation, chemical industry, etc.

Product Principle of Starch Hydrocyclone

Under higher pressure, starch milk pump out through feed into the middle of the cylinder block mouth cavity, the pressure is 0.4-0.7 Mpa, starch milk flow into the vortex tube import, and along the vortex tube into the tangent of the vortex tube internal, in the vortex tube materials according to the various components of the helical make the rotary motion, produce centrifugal force when descending to the cone part of logistics, because of the various components of the relative density, Different diameters and different shapes cause different centrifugal power, the relative density of large components-starch get larger centrifugal force, along the spiral movement was thrown down the wall and cone wall exactly exit flow; And the relative density small protein and water get smaller centrifugal force, the spiral movement, down the resistance of the exit, exactly formed the direction of rotation in inverse spiral eddy current on top exit runs, so as to achieve the purpose of the various components of the separation.

Product Advantage of Starch Hydrocyclone

1. Full stainless steel without any corrosion;

2. Advanced surface treatment craft, oil, and dirty resisting;

3. Widely applied in starch extraction in starch processing plants;

4. Multi-function of concentrating, refining, washing and clarifying for hydrocyclone group.

5. Cyclone pipes are made from the material of reinforced nylon with high strength, better abrasive resistance, and excellent separation result.

6. Hydrocyclone designing is adopted to get better starch separation according to the features of the different material.

7. The pipeline of hydrocyclone group passes computer optimization design, with compact and elegant structure.

8. Special sealing design, friendly operation.

Technical Parameters of Starch Hydrocyclone

|

Model Number

|

Specification(mm)

|

Flow

|

Power

|

Degree

|

|

GD-XL-273

|

10/15/30

|

7-12.5

|

4-7.5

|

8,12,21

|

|

GD-XL-350

|

10/15/30

|

12-25

|

5.5-15

|

8,12,21

|

|

GD-XL-430

|

10/15/30

|

15-30

|

7.5-18.5

|

12,21

|

|

GD-XL-600

|

10/15/30

|

80-110

|

30-45

|

12,21

|

EN

EN

fr

fr  es

es  it

it  pt

pt