Mechanization of cassava production operations in response to the presentations, discussions were held targeted at addressing the following questions.

(a) What technologies are out there for the farmers?

(b) What machinery can be accessed to help small scale farmers?

In response to the questions above, it emerged that some cassava production machinery were developed at IITA such as prototype manual lifters / harvester with potential for commercialization for the benefit of cassava farmers. However, they may not be needed by the typical small scale farmers. A practical approach is to have some of these machines rented through a service providers. Several success stories on service provision exist, for instance use of stem cutters from Malaysia that can be easily fabricated and adapted for local conditions in Nigeria. However, this has to be done with full respect to intellectual property rights, for instance through joint-venture initiatives that can lead to producing such equipment locally. It was noted that, although service provision is a viable option, it can also be constrained by several factors such as the ones listed below:

(a) Lack of proper land preparation, that is stumping or removal of stones.

(b) Planting of cassava in non-linear rows that is not compatible with mechanization of cassava production operations.

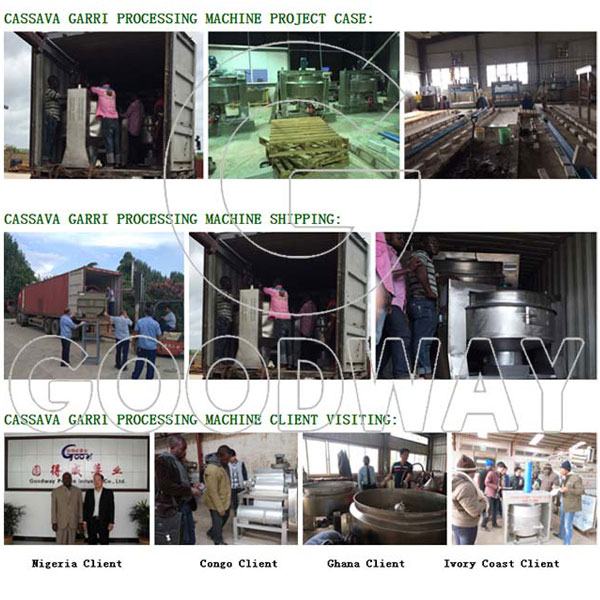

According to mechanization of cassava production, our company could supply four kinds of

cassava processing plants, as following:

1:

cassava starch processing machine line

2:

cassava flour processing machine

3:

cassava chips processing plant

4:

garri processing plant

EN

EN

fr

fr  es

es  it

it  pt

pt