What starch processing companies fear most is equipment outage and malfunction. They cannot afford to wait for raw materials and construction period, and all they lose is money. Is there any way to ensure normal production efficiency and reduce fault repair costs?

Capacity expansion

The production capacity of starch equipment should be slightly larger than the actual processing capacity, and the equipment load should not be heavy, which can effectively alleviate the throughput pressure of the equipment.

If there is excess production capacity, the equipment will bear the load, causing excessive wear and tear of the equipment, shortening the service life, and causing a higher failure rate; if the production capacity is too small, the equipment will idle for a long time and waste of resources will not be feasible.

Equipment branching

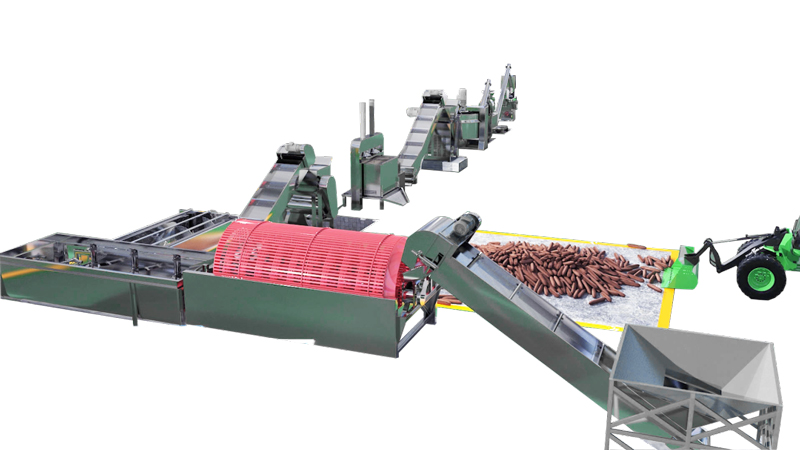

This method is particularly suitable for companies with large production volumes. Split the large-capacity starch production line into two lines and run them simultaneously. For example, split the 8-ton-per-hour production line into two 4-ton-per-hour production lines.

The advantage of this is that once the equipment fails and stops production, there is another line that can operate normally, reducing economic losses.

The cleaning and crushing environment of actual cassava starch processing is relatively poor. There are many hard debris in the freshly harvested raw materials, such as stones, soil clods, woven bag tissue, vines, and weeds. When they are twisted into the equipment, it will cause abnormal A faulty shutdown usually takes 20-30 minutes to resolve. At this time, the benefits of split-line processing are reflected.

Of course, if you really encounter a difficult problem and there is no way to solve it, please contact us as soon as possible to prevent small problems from turning into big problems and causing greater losses.

Nanyang GOODWAY Machinery Equipment Co., Ltd.

-

GOODWAY was founded in 1991. As a national high-tech enterprise, GOODWAY has focused on the innovative research and development and technological improvement of potato deep processing machinery for 32 years.

-

We always insist on providing sturdy and reliable processing machinery and practical technology to potato deep processing users around the world! Create a comprehensive processing solution for users.

EN

EN

fr

fr  es

es  it

it  pt

pt