If you want to invest in a vermicelli processing factory, you can't simply buy a vermicelli processing equipment, build a factory, and hire labor to start the business. A long period of preparation and planning is required from the preparation of funds, formal documents, land leasing, factory construction, equipment entry, raw material procurement, staffing, etc. So what do the specific preparations include?

1. The location of the vermicelli processing plant should be

flat and open. The basic requirements for choosing a factory location: first, stay away from densely populated urban areas to avoid noise pollution; second, choose a location with convenient transportation to facilitate product sales and transportation; third, stay away from fertile farmland to avoid water source environmental pollution.

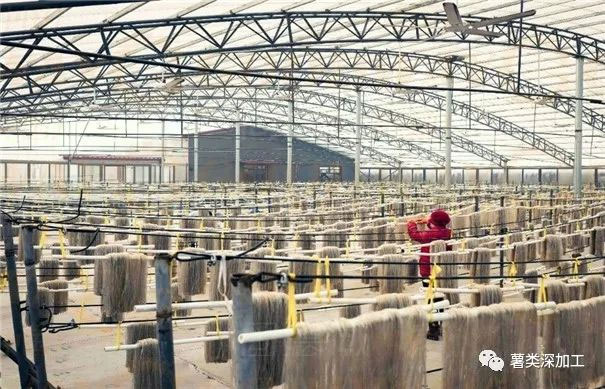

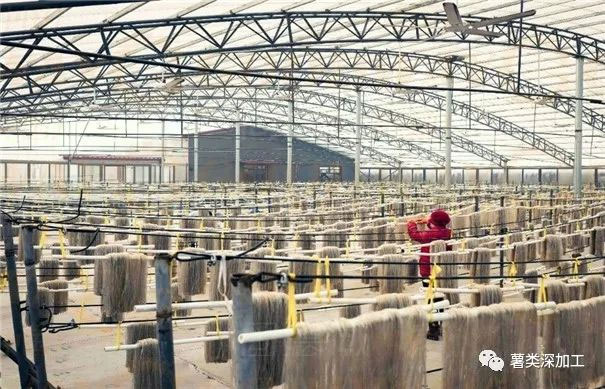

However, GOODWAY's vermicelli machine processing technology has been significantly improved. The fully automatic slurrying process vermicelli machine production line basically adopts mechanical operation and is highly automated. It only takes 2.5 hours from starch and slurry to dry vermicelli coming out of the machine. The stainless steel enclosed space Processing without adding alum basically solves the environmental pollution problem caused by traditional vermicelli processing.

2. Infrastructure work for vermicelli processing factory

This part mainly includes processing and production workshops, warehousing workshops, packaging workshops, office areas, activity areas, etc. It also includes specific details such as factory planning and design, equipment installation wiring, water and electrical pipelines.

Generally, experienced equipment manufacturers such as

GOODWAY Potato Industry will provide users with plant design and planning plans, equipment layout drawings, etc. in advance, including solutions to the above tasks to solve users' worries.

3. Conduct market research, determine product positioning and clearly target customer groups for factory production, whether for domestic trade or foreign trade, and for the high-quality, high-end vermicelli market or the mid-to-low-end vermicelli market.

These factors determine market pricing, product levels, and vermicelli production quality, and also determine which type of vermicelli machine equipment you need to choose.

The current vermicelli machine equipment manufacturing market is roughly divided into fully automatic vermicelli vermicelli production lines and small and medium-sized semi-automatic vermicelli machine processing equipment, which respectively represent two types of vermicelli processing scale, technology level and vermicelli product grade.

The configuration, specifications, output and price of the vermicelli processing production line are carefully divided to facilitate users to make choices based on their personal financial level and consumer market launch.

EN

EN

fr

fr  es

es  it

it  pt

pt