The sweet potato starch production process has a long history. Raw materials are easily available, and the technology of sweet potato starch processing equipments is relatively mature. However, when sweet potato starch is processed, these two issues should be noticed.

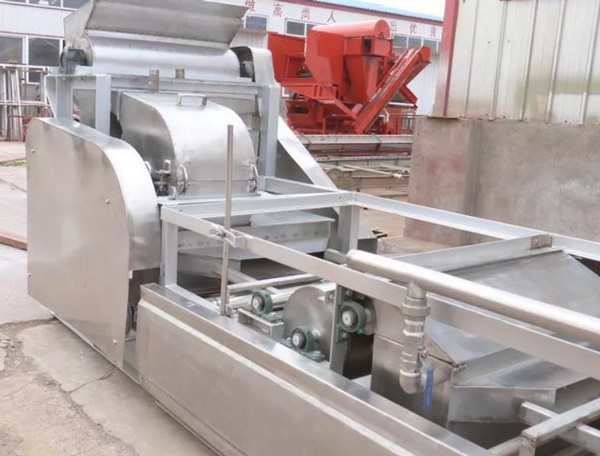

1. Cleaning row materials

The roots of sweet potatoes are under ground, and of course, they will carry some soil after harvest. Before processing sweet potato starch, it is very necessary to clean them. Moreover, the mud and cracks in the sweet potato buds and cracks are difficult to clean. Multi-stage cleaning equipments of sweet potato starch processing equipments can be used at this stage to use various cleaning methods totally.

Only after the raw materials are washed can the impurities of sweet potato starch be reduced. Otherwise, the quality of starch can hardly guarantee. After the dry starch is produced, if the quality is not good and cannot be sold, the processing cost of sweet potato starch processing equipment can be high.

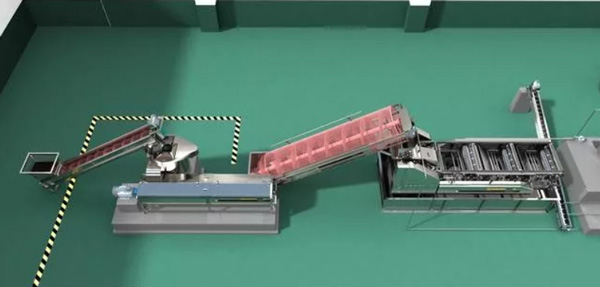

2. To crush and extract

Sweet potato crushing is an important step in the processing of sweet potato starch. At this stage, care should be taken not to over-crush. Over-crushing will only waste resources and reduce efficiency. It should be crushed properly. When separating and extracting, it should be processed in time with sweet potato starch processing equipments just to avoid quite long contact with the air, causing browning of the starch and affecting the appearance of the starch.

This stage involves several important steps of processing sweet potato starch. Now the current sweet potato starch processing equipments have been able to integrate crushing, separation, and extraction, which can improve processing efficiency and effectively avoid browning of sweet potato starch.

If you can choose the right and appropriate sweet potato starch processing equipments, and stick to these two points mentioned above, you don't need to worry too much.

EN

EN

fr

fr  es

es  it

it  pt

pt