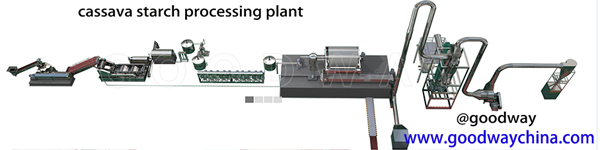

Immediately after the cassava harvest period, many farmers want to buy

cassava starch processing equipment, then how to choose the appropriate tapioca starch processing equipment? What are the things that need attention?

1. According to the requirements of finished starch

If the starch quality requirements are general, some fine filtration single machines can be temporarily configured without selecting the tapioca starch equipment. If you want to produce high-quality white starch, you must configure a complete set of tapioca starch processing equipment. Fine filters, mud removal and sand removal are essential.

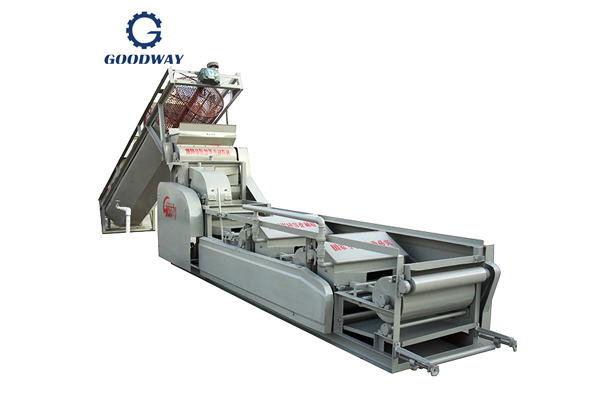

2. Choose more advanced equipment

Some

cassava starch processing line processes are relatively backward, especially in the stage of crushing and extracting starch, the extraction rate is very poor, and this equipment is not only inefficient, but also causes great waste. It is recommended that you choose a more advanced tapioca starch processing equipment, which is not only efficient but also has a very high starch extraction rate.

3. Choose equipment with stable performance

Some equipment performance is very unstable, and it is in a state of being put into production, which will seriously affect the processing efficiency and quality of cassava starch. Although the price may be relatively low when purchasing such a tapioca starch processing equipment, when such a tapioca processing machine is put into use, many problems often occur, which is not worth the loss. It is recommended that you inspect and select high-quality tapioca processing equipment with stable performance.

In general, manufacturers who have been in the starch equipment industry for many years are very strong, because time is the best test for their

cassava starch processing equipment.

4. Choose easy to repair and maintain equipment

Even the best equipment will fail, but some equipment is very cumbersome to repair and it is not convenient to disassemble and replace parts. When selecting cassava starch processing equipment, it is necessary to select those machines that are easy to repair and maintain, so that even if the equipment occasionally fails, it can be solved in time, and will not delay too much time, thereby ensuring the efficiency of starch processing and improving the quality of finished starch. The reason why starch quality can be improved is that the interruption of production will cause browning of starch and seriously affect the color of starch.

EN

EN

fr

fr  es

es  it

it  pt

pt