Regardless of the scale of your investment, you need to make adequate preparations in advance to open a cassava starch processing starch factory. It takes a certain amount of time, energy and capital to successfully start a starch factory. Production sites, equipment, raw materials, and labor are indispensable. For those who are ready to enter this industry, it is important to understand the investment cost and production cost, and start their own entrepreneurial journey according to their own strengths to reduce risks.

1. Land cost

Land is needed for investment and construction of factories, and sufficient production plant construction area must be prepared in advance. Whether it is buying or renting, it is a long-term investment. It is necessary to find a location with convenient transportation, close to the farmer’s market, complete water and electricity facilities, and away from the urban area, so as to control the initial investment cost. In addition, it is necessary to plan and design the functional zoning of the processing plant to be opened and the equipment occupation in advance. Generally, the company that produces equipment will provide services such as supporting site planning and designing plant drawings.

2. Cost of procedures

To open a starch processing plant, the procedures must be formal and complete. Depending on the size of your plan, the required procedures will vary. For family-style production, business license and sanitation permit are required. If it is a large and regular food production plant, in addition to business license and sanitation permit, tax registration certificate, food production permit, QS quality certification, etc. Inspection, these procedures will incur a fee. Some provinces, cities, and regions require different procedures. In short, they must be completed in accordance with local regulations and will not affect subsequent production, processing and sales.

3. Equipment cost

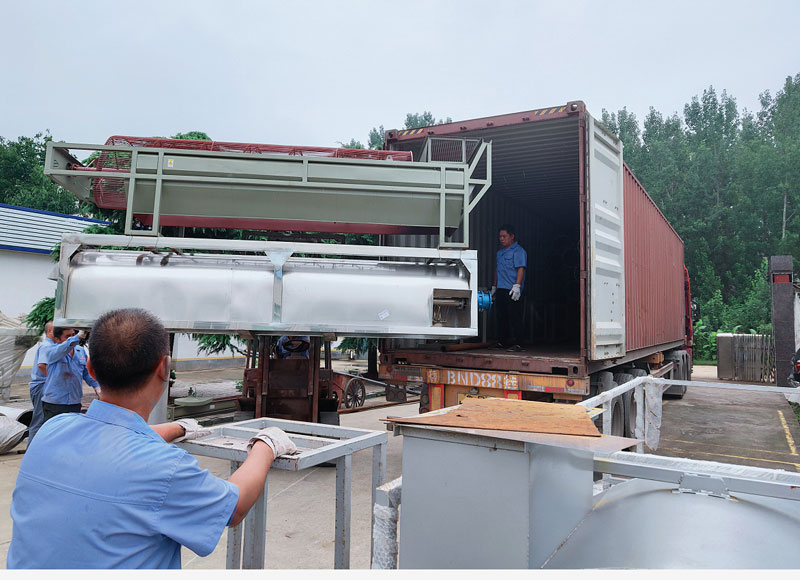

This is an important capital investment for the establishment of a cassava starch processing plant. Starch processing is seasonal processing, concentrated in autumn and winter. Customers and friends who want to invest in building factories, after preparing land, procedures and other issues in advance, began to inspect professional tapioca starch processing equipment on the market in spring and summer, and went to cassava processing equipment manufacturers to visit and understand the types of equipment and place orders as soon as possible. The equipment manufacturer then schedules the construction period to start manufacturing equipment, and delivers the equipment before the start of the autumn and winter processing season, installs and debugs the equipment in place, so that it can be put into use smoothly.

The price of processing equipment such as cassava starch machine is customized according to your processing volume and configuration, and the price will also be adjusted according to the details. The equipment is cheaper if the processing volume is small and the configuration is low; the equipment price is high if the processing volume is high and the configuration is high. You can listen to the suggestions and analysis of professional sales staff and choose the appropriate equipment according to your needs.

4. Labor cost

Labor is also very important. A series of tasks such as production, management, sales, transportation, and packaging require someone to perform operations. This should be based on the scale of the planned plant to recruit staff. The degree of automation of the equipment is different, and the number of processing personnel you need is different. The higher the degree of automation, the fewer operators, and only a professional regulator is required to monitor the operation of the equipment.

5. Raw material purchase cost

Starch processing plants: need to purchase a large amount of fresh cassava (tubers) and use professional starch processing equipment.

6. Transportation cost

Transport a large amount of fresh cassava purchased before processing, and after processing, the finished dried starch or dried vermicelli produced should be packaged and transported to all parts of the country.

7. Promotional sales cost

The cost of this part of the production depends on which sales method the processing household prepares. If it is only for the surrounding farmer’s market and household households to buy in bulk, there is no need for advertising design and promotion. If you use e-commerce, wholesale, and network marketing, you need a certain amount of promotion expenses. You should make a reasonable choice based on market conditions and product positioning.

EN

EN

fr

fr  es

es  it

it  pt

pt