There are two kinds of cassava sieving machines used for cassava starch production process: fine fiber sieve and centrifugal sieve.

Firstly we introduced the fine fiber sieve, it is widely used in potato and

cassava processing machine for starch processing. The commonly physical operation which is used for the separation of cassava residues from cassava slurry by interposing a medium(filter) through which only the raw starch milk can pass (depending on the pore size and filter thickness). Oversize particles in the feed cannot pass through the lattice structure of the filter, while fluid and small particles pass through, becoming filtrate.

Main Features of Fine Fiber Sieve:

1. All parts contact with the material is stainless steel, no material corrosion.

2. Sieve made of nylon with the good hygienic condition.

3. Advanced surface treatment technology ensuring its good appearance and resistance of oil and dirt.

4. Big capacity, lower power consumption, stable operation, and high starch extraction ratio.

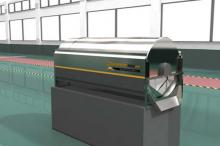

Secondly, we introduced the centrifugal sieve, it is widely used for starch extraction in starch processing plant. The slurry is pumped directly to the center of the conical rotating screen basket. Under centrifugal force, the starch is flushed through the screen onto the back of the basket and leaves the centrifugal sieve while fiber/pulp sliding off the screen and leaves the sieve from the front outlet. Water spraying nozzles inside and outside of the basket ensure fiber/pulp washing and prevent screen blockage.

Main Features of Centrifugal Sieve:

1. Combining the latest technology and years experience into a whole.

2. Key components introduced abroad, long service life, low maintenance cost.

3. All parts contact with the material is stainless steel, no material contamination.

4. Sieve basket is calibrated through dynamic equilibrium by domestic authority body.

5. Sieve made from laser perforating on titanium alloy plate.

6. To facilitate the automatic design for centrifugal sieve group. CIP system and chain automatic control can be easily realized.

7. Advanced surface treatment technology ensuring good appearance and resistance of oil and dirt.

8. Nozzles tested by strict examination in pressure and flow rate.

9. Big capacity, low power consumption, stable operation, high starch extraction, and easy installation.

EN

EN

fr

fr  es

es  it

it  pt

pt